RoboDK Software Helps Cut Aircraft Washing Time by 95%

Wilder Systems uses RoboDK robot programming features for automated airplane washing. They designed the first robotic "drive-through" washing system using a F-16 aircraft and two Fanuc robots.

Robot Machining for Sculptural Precision

Discover how RoboDK empowered artists like Neoset Designs to use robotic machining for creating intricate and precise sculptures with unparalleled efficiency.

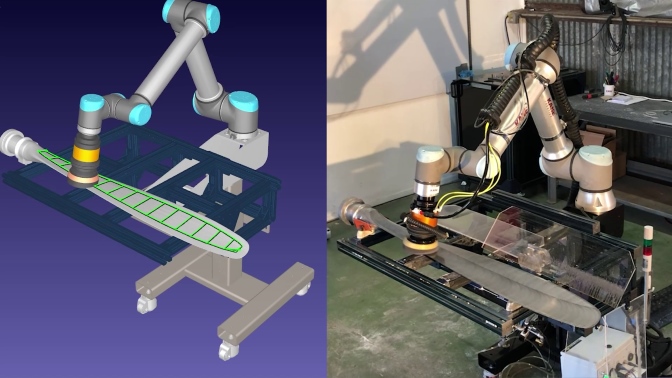

Orbital Polishing with RoboDK

Kane Robotics used RoboDK to automate robotic orbital polishing, achieving flawless surface finishing with unmatched precision and efficiency.

NASA Used RoboDK for Multi-Robot Inspection

NASA enabled dual robot inspection with RoboDK, enhancing efficiency and precision in quality control processes.

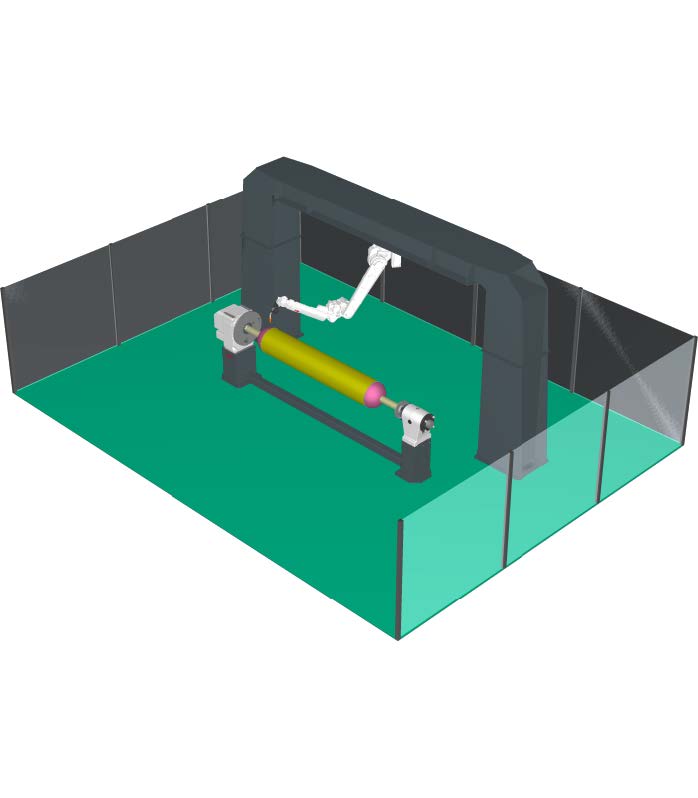

Robot Welding with External Axes

RoboDK simplifies robot welding automation, synchronizing robots and welding positioners to optimize automated welding workflows.

Robot Painting with Custom API Integration

RoboDK enables precise robot painting through innovative applications, such as creating instant portraits with robotic precision and supporting fully automated, 24/7 painting processes without human intervention.